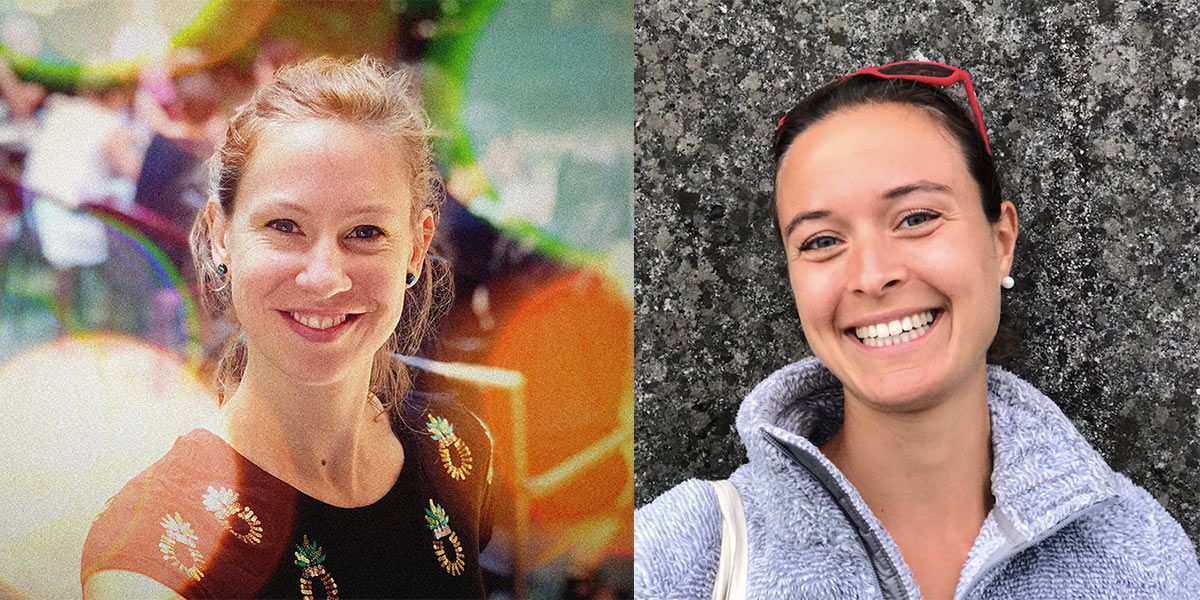

Pauline bag printing with Leni Lecker and Matthias

What an exciting adventure. A heart-felt project has finally come true. Long planned and longed for, but as it is, it takes longer than you think. The design idea is not yet right, Corona comes in between and, and, and. But finally the time had come. Tada, we printed Pauline bags.

It was important to me that we use vegan colors and they should also be water-based. It wasn’t easy to find someone who could fulfill these requirements, because I wanted to print gold on black, a light color on a dark ground. This is usually done with synthetic colors to achieve a high opacity. But in my research I found what I was looking for, at the artists’ collective Stattlab e.V. in Wedding in Berlin.

We did a silkscreen workshop with Jördis Hirsch, who went through all the individual steps with us and supported us lovingly in bag printing.

Then let’s go on a little printing journey:

First we prepared the screens for the image exposure. For this purpose I applied a light-sensitive emulsion to them. This happens in the dark with red light, so that the emulsion is not exposed before. This requires a delicate touch to achieve an even layer and to be able to print the image neatly afterwards.

While the screens were drying, we prepared the design template and then used it to expose the screens. Then we went on with the washing of the screens. The unexposed parts on the screen are washed out with the help of a kärcher. That was fun. Especially because then the image appears as if by magic.

We decided on a design with one color because it is even more time-consuming to print several colors. You would need several screens and printing processes for it. But we were there 5 hours anyways to hand print all bags😅.

Then we started with the actual printing. We decided to print 2 different types of bags. One with thicker fabric and one with thinner. Both made of organic cotton.

So we started with the thicker bags. This was not so easy because the screen got clogged relatively quickly, so that the flight line of our butterfly was quickly not so pretty anymore. So after a few bags we decided to clean the screen to try it again, but then we switched over and tried the thinner bags.

Then there was the next difficulty, because they are a bit smaller and did not fit on the board on which the bags are mounted, so that they don’t slip during printing and you can print on them several times. So we had to mc gyver a little bit, and we were not sure if that would work at all. But our cobbled together print setup worked wonderfully. The print was much better than with the first bags, because the fabric is not as absorbent as the other kind. That really motivated us. I printed and Matthias captured lots of photos and blow-dried the bags. Jördis supported us. We really got into the flow and suddenly everything went like clockwork.

After we had finished the thin bags we cleaned the screen and went back to the other bags, excited about the results. Since we were now a really well established team, they didn’t cause us any more problems. Here we still had the intermediate step with blow-drying between the two printing processes. Finally, the final cleaning of the screens was done, where I removed the image out of the screens with the help of a solvent and kärcher.

Exhausted and happy, we made our way home.

Here you get the limited bags, handprinted by us for you. We are already out and about with our bags and hope you like them as much as we do.